Top 5 Transparent LED Screen manufacturer in the World 2025

2024-12-17

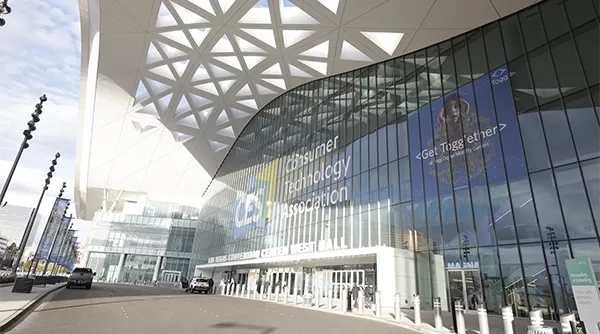

Glass Facade Display Solution | Bank of Montreal Opens in Downtown Toronto: 250m² MUXWAVE Holographic Invisible Screen Captures Attention

2024-12-25Welcome to our Transparent LED Display Factory, where cutting-edge technology and precision manufacturing come together to create industry-leading visual display solutions. As a trusted leader in the transparent LED display market, we take immense pride in producing high-quality, innovative products that are transforming industries ranging from retail and architecture to advertising and entertainment.

Whether you’re a potential customer, business partner, or industry enthusiast, our factory tour will showcase how we consistently deliver top-notch products that meet the evolving demands of today’s digital world.

Welcome for a Tour

Join us as we explore how our transparent LED display screens are designed, manufactured, and tested to ensure they provide exceptional performance, clarity, and versatility. Ready to see where innovation happens? Let’s begin!

About Our Transparent LED Display Factory

Our Transparent LED Display Factory is located in a cutting-edge facility, spanning approximately 7,000 square meters. This expansive space allows us to efficiently house our entire production process, from design and prototyping to final assembly and testing. As a dedicated manufacturer of transparent LED display screens, we leverage advanced technology and automated systems to ensure the highest standards of quality and precision across all stages of production.

At the heart of our operations is a commitment to innovation and excellence. Our factory is equipped with the latest manufacturing tools, ensuring that each transparent LED display meets the specific needs of our customers while pushing the boundaries of display technology. With our full-cycle production capabilities, we handle everything in-house—from sourcing high-quality raw materials to cutting-edge testing facilities that guarantee the durability and performance of our screens.

As one of the industry’s leading transparent LED display manufacturers, we take pride in being able to offer customizable solutions that meet the unique needs of our clients. Whether it’s for retail displays, architectural installations, or large-scale advertising projects, our factory’s comprehensive manufacturing process ensures that every transparent LED display screen we produce is of the highest quality and ready to perform under diverse conditions.

Our Full-Cycle Manufacturing Process

At our Transparent LED Display Factory, we pride ourselves on our comprehensive, full-cycle manufacturing process, which allows us to maintain complete control over the quality and precision of every display screen we produce. From initial concept and design to final assembly and testing, we ensure that every step of the process meets the highest industry standards. Below is an overview of the key stages involved in our full-cycle production:

1. Design and Development

The journey of our transparent LED displays begins with meticulous design and planning. Our expert engineering team works closely with clients to understand their specific needs, ensuring the display’s design aligns perfectly with the intended application—be it for retail, architecture, or advertising. During this phase, we integrate the latest technology and design innovations to optimize transparency, visual quality, and durability.

2. Raw Material Sourcing

We begin sourcing only the highest-quality materials for the production of our LED displays. This includes LED chips, transparent substrates, and other essential components that ensure superior performance. We maintain strong relationships with trusted suppliers to guarantee the consistent quality of our materials.

3. LED Encapsulation and Testing

Once materials arrive, we move to the LED encapsulation process. This involves the careful sealing of LED chips in transparent materials, allowing for maximum light transmission while maintaining durability and protection. The encapsulation process is followed by rigorous testing to ensure that the LEDs perform optimally in various environmental conditions.

4. SMT (Surface Mount Technology) Assembly

Next, we utilize SMT technology to mount the LED components onto the transparent substrates. Our automated SMT lines ensure precise placement of tiny components, resulting in reliable and accurate assemblies. This stage is crucial for ensuring the longevity and efficiency of the final display.

5. Programming and Calibration

Once the display is assembled, our engineers program the display’s control systems to ensure perfect synchronization between the LEDs. Calibration is performed to ensure optimal brightness, color accuracy, and uniformity across the entire screen. We also fine-tune the display’s transparency and adjust it to the desired level based on specific client requirements.

6. Aging and Quality Assurance

To guarantee the durability and performance of our transparent LED displays, we subject them to an aging process. This involves running the displays for extended periods under controlled conditions to identify any potential defects or weaknesses. During this phase, we also conduct comprehensive quality assurance tests to check for issues such as pixel performance, brightness uniformity, and overall reliability.

7. Final Assembly and Packaging

Once each display passes quality assurance, it is carefully assembled into its final form. Any necessary frame, casing, or additional components are installed, and the unit is packaged securely for shipment. We ensure that every display is ready for installation and use in its intended environment.

8. Delivery and Installation Support

Finally, we deliver the finished products to our clients, providing detailed installation guides and technical support as needed. For large-scale installations, our expert team is available to assist with setup and ensure the transparent LED displays are properly integrated into their respective spaces.

By overseeing every step of the manufacturing process, we ensure the highest quality standards and deliver custom transparent LED displays that meet the specific needs of our clients. This end-to-end approach not only guarantees precision but also allows us to provide flexible, scalable solutions for a wide range of applications.

How to Plan Your Visit

Póngase en contacto con nosotros: To schedule your visit, simply reach out to our sales or customer service team. Let us know your preferred date and time, and we will work with you to coordinate your tour.

Location: Our factory is located at [Factory Address]. We are conveniently situated with easy access from [nearest major city or transport hubs], making it easy to visit from anywhere.

Tour Duration: A typical factory tour lasts between [insert duration], depending on the depth of your interest and the specific areas you’d like to explore.

Health and Safety: Your safety is our top priority. During your visit, we follow strict health and safety protocols to ensure a safe environment for all visitors. Our team will provide guidance on safety procedures during the tour.

What to Expect During Your Visit

- A comprehensive overview of our manufacturing process, including design, production, and quality assurance.

- Live demonstrations of transparent LED displays in action, including interactive presentations showcasing their unique capabilities.

- The opportunity to discuss potential collaborations, customized solutions, and how our transparent LED displays can enhance your business.

- A chance to meet with our R&D team and learn about the latest innovations we’re developing in the world of transparent LED technology.

We look forward to hosting you at our factory and providing a comprehensive, hands-on experience that showcases the quality, innovation, and precision that make our transparent LED displays the best choice for your business needs.

Book Your Visit Today!

To schedule your visit or inquire about tour details, please contact us at info@muxwave.com. We can’t wait to welcome you to our facility and show you how we’re shaping the future of transparent LED display technology!